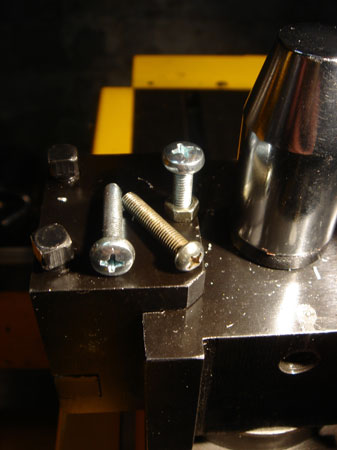

One thing that was bugging me was the hardware on the tool holders. The height adjusting screw (laying down on the right) was pretty wimpy. I wanted something more positive engagement so I got a stainless one. As you can see the head is almost twice as big.

Next up where the bolts that clamp the tool in place. They are little square head things but I replaced them with a big ol' stainless bolt. I wanted ones that would accept an allen key but they didn't have any metric ones at the local hardware store. They actually worked pretty well, because the machine came with a special tool for these but...

The bolt on the left is the one that came with the machine. The tip used to look like the stainless one on the right...but I flatted the heck out of it clamping a round boring bar. I could barely screw the thing out of the holder. The idea was the stainless ones would be a bit harder.

Of course the most obvious answer would be to mill some flats on the round boring bar but I'm not supremely confident that I can clamp them properly for milling and didn't want to screw up on the alignment of the flat.

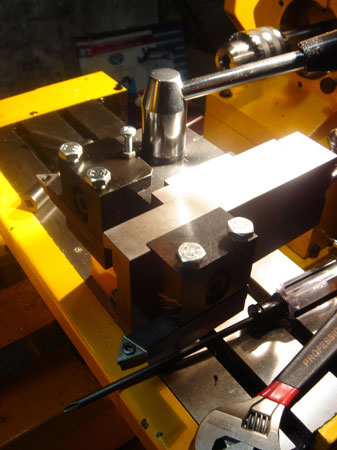

Well, here is the finished product. Seems to be working fine so far. You can see the weird compound slide with a tool holder attached in the foreground. The usable travel is only about an inch and a half, so my tapering will be fairly limited. It seems to work quite well though for it's unusual configuration.

The construction seems much better than, for example, the vise that came with the machine. I elected to replace that immediately with a precision ground milling vise from Enco tools.