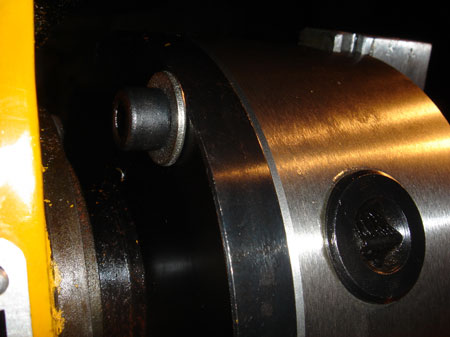

This baffled me for a while. Tangoromeo said his chuck was "dangerously" loose when it arrived so I wanted to check mine. However, there was no way any kind of allen key was going to fit back there.

So I think maybe that's not how the chuck comes off. I mean, they wouldn't build it so you can't get a tool in there would they? Answer: of course they would.

The key in the photo is the one I "modified" in the next photo.

I clamped this bugger in the vise and went after it with a dremel and abrasive disc. No muss no fuss.

Want to know what's funny? See the bolt by the red arrow? I can't even get my short allen key in there! Hope the bolts are tight...

So that's how it comes off. The blue binder was there to protect the ways if I dropped the chuck. All right! Now we are cooking. I cleaned up the back of the chuck and the faceplate and slapped them back together.

Then I chucked up a piece of 1" rod, fired up the machine...wobble wobble wobble wobble wobble. Huh, that's not cool.

Upon closer inspection of the chuck/faceplate I found the gap between the two was not even. Does this mean one of the mating faces was cut badly? This was my fear until I discovered that there was slight gap between the bolt head and the back of the faceplate. The bolt was bottoming before the chuck was tight! Great.

So I ran down to the hardware store and bought three stainless washers to take up the slack in the bolt and this seems to work just fine. The chuck reads square using a dial indicator.

Well this isn't much of a fix or mod...but I found that I saved my arm a lot of trouble by using a socket adapter in my power drill to run the jaws in and out when I have to make a big move.