I worked at a fabrication shop in LA for a little over a year. When I moved up to the Bay Area I continued to work on refining a fire pump project.

EP Industries - CEM CAFs division

This shot was taken in Livingston, MT during a tour I made of ID and MT demonstrating the D-CAFs 24v system for various fire departments.

The system runs off two car batteries, a 3HP DC motor and will deliver 60gpm with straight water. Since the pump is positive displacement I was able to draw water, without priming the pump, 6 feet up hill through a 30 foot 1.5" ID hose. No one had ever seen that before.

When the pump is set to produce compressed air foam (CAF) the system only consumes 2-3gpm of water and is intended as a "first on scene" system that can be coupled to a 35 gallon tank and carried in the back of a truck or SUV and provide 10-15 minutes of continuous use. A typical centrifugal system would exhaust the 35 gallons in a matter of seconds. .

I custom built a system that consisted of the D-CAFs (from EP Industries), two commercial optima batteries, 35 gallon water tank, 2 gallon surfactant tank, and two pieces of 30' 1.5" ID hose for the intake and output hoses.

I also reworked a smooth bore brass nozle to accept a 3/8" NPT nozzle that produces different fan patterns for fogging...I'll have to remember to take pics of that!

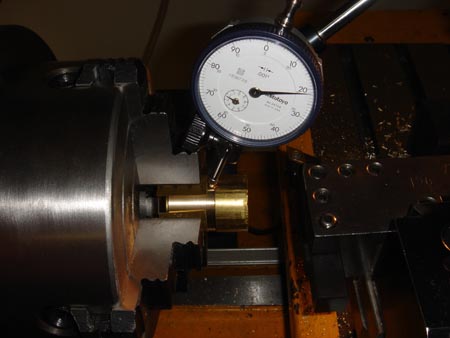

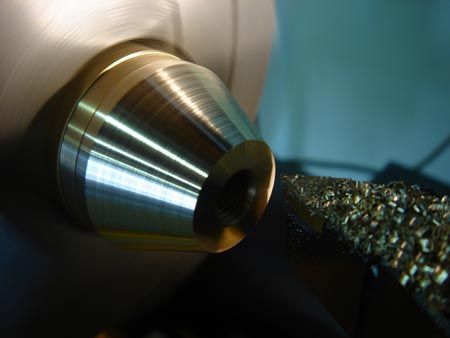

The next piece I had to make was a dropper/pick-up for the surfactant tank. Here is my Clausing compound and KDK post in action.

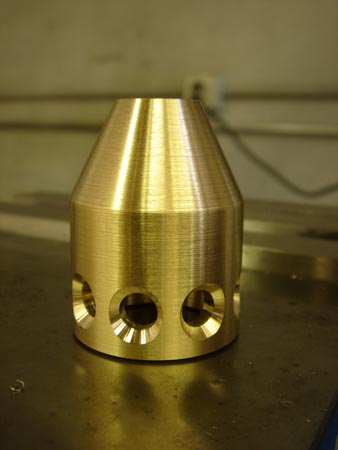

Well, not quite done. I forgot to take pics again but I set this up with my ST 3 jaw and the little rotary table featured in my "rotary table re-machine."

Looks nice and works great! Too bad it sits inside a bucket with the lid on.