Skiving Tool

I ran across this type of tool on the Home Shop Machinist board. I had never heard of it before. It seemed a little crazy so rather than buy into the "he said she said" thing on the message board I thought I'd try it for myself.

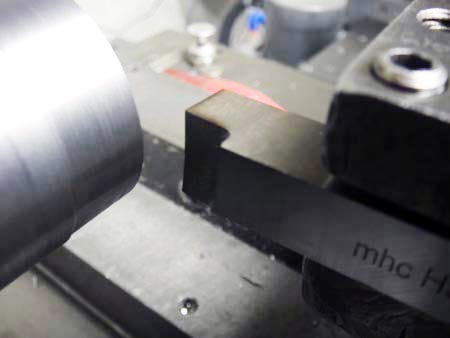

This was my first attempt and didn't follow any measurements. I just guesstimated. Me, a grinder, and a 1/2" piece of HSS.

The goal was to produce a nice finish on hot roll.

I did some research, and I'm not sure this is really a skiving tool. Click here for a more in depth description and images I struggle to understand.

Not to be dissuaded, I pressed on blindly.

The face angle, I'll call it "lay back" should probably be steeper. However, this configuration works surprisingly well, especially on small diameters.

I did notice that it works best when razor sharp and tended to dull pretty quickly. Probably because the angle is not ideal.

You can't really tell in the photos but I ground clearance on all the sides and the "face" has the radius of the grinding wheel. The end you can see is ground squared and honed with a diamond stone.

So I chucked up a 2" piece of HRS. I used 4 different tools for comparison, starting on the left.

1) Seco DCMT roughing chip breaker

2) Generic TCMT insert with large nose radius

4) Ground HSS

5) Skiving tool

This piece of HRS turned surprisingly well with all the tools. However, the skiving tool isn't a mirror finish but it feels perfectly smooth. I think the HSS and SECO tool produced similar finishes but I ran the carbide at 1400 RPM and the HSS only at 800. The TCMT was by far the worst finish.