I'm taking a CNC machining class and I had to make up two sets of soft jaws (for two vises) to run some parts.

After completing my class assignments we were encouraged to work on our own projects. I decided to run some new prototypes for a design change to the LC/EF storage holder.

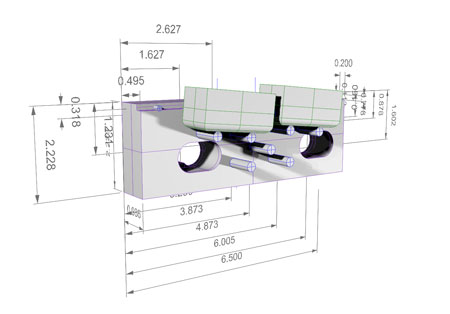

This Rhino model helped me determine the locations of all the dowel pins. Using ordinate dimensioning, I could just plug the coordinates into the CNC.

Here is the final result. Before going to the CNC I milled the jaws on a conventional mill, including the pockets for the vise screws.

I figured I could do this in the same time it would have taken to program it since I would only need two sets of jaws.

The holes were center drilled, drilled and reamed on the Haas. Of course I used the LC/EF to locate the work offset coordinates!

Ruh ro. The drawing I was working from was the wrong revision! So much for all that careful planning. Turns out that some of the holes are too low. Now what? After determining exactly how low, I found that I could use some 5/16 drill rod and be within about two thousands of where I needed to be.

Close enough. These pins just set the angle and a degree here or there won't matter. I turned down the drill rod to fit the 1/4" reamed holes. I had to throw two of them out because I turned them down too much.

So you can see the big pins in place and now the angle is right. You can also see how the pins port rude less than the width of the LC/EF holder. It's enough to locate the part and I don't have to try and match up any holes on the other side.

I have no idea if this is a good way to go about it, I came up with the whole arrangement on my own but it seemed to work fine. By removing or inserting particular pins, the same set of jaws can hold the LC/EF holders through operations on all six sides.

On the right you can see two parts in place. The left vise is empty but you can get an idea of the pin arrangement.

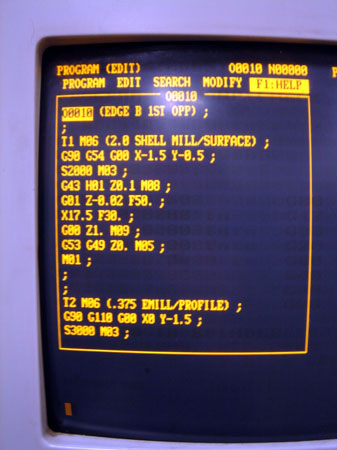

Mmmm hand written G code.