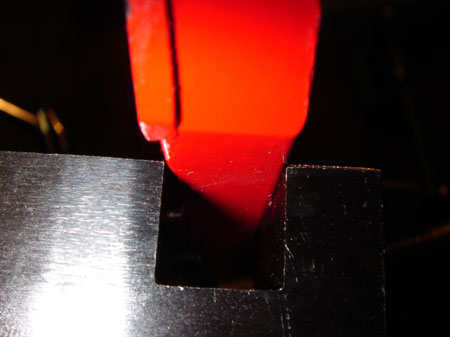

GAAAAAHHHH! Are you serious? This was my first indication that something was going wrong, very wrong. Let's see...1/2" tools...1/2" tool holder...all supplied with the machine...ohhhh of course, the tool holder is metric. Called Shoptask and they said send them back and we'll fix em or do it yourself. Well, making my first cuts on hardened steel wasn't planned but here we go.

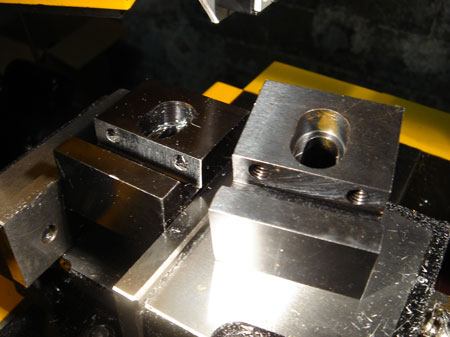

I blocked the tool holder up with parallels in a previous step. I wasn't sure everything was square, since this would be my first cut with this machine. I just ran the bit up and down with the machine off and the clearances looked good. I aligned the table and the vise with my LC/EF before this. I ordered a 3/8" 4 flute endmill just to do these tool holders....should have ordered two.

Man the chips that come off steel are ridiculous. Tiny little needles ready to stick into anything fabric or flesh. Nasty stuff.

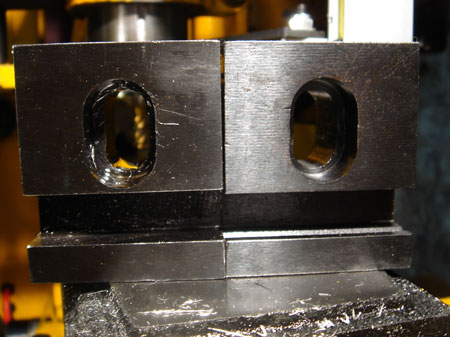

Why should I have bought two endmills? Cause I blew one up. I was taking my last finishing pass on my last tool holder (3 holders and 4 passes on each one). I was trying to take it real easy.

Anyway, last pass under power and as soon as the tool touches metal...bang my tool blows three teeth and almost flips the heavily clamped tool holder onto the floor. I didn't take any pictures because I was scared and embarrassed. I have no idea what happened.

Suffice to say, after some hand wringing, swearing and staring in disbelief I manned up and took out the 1/4" endmill and finished up the cut.

All that for about .030" inches. Well, now all my tools fit, quite nicely if you are asking and I also have the satisfaction of a job...satisfactorally done for someone who has never run a milling machine before.

The tool holder on the right has not been cut yet and is the one that caused a ruckus. I still haven't found the pieces of tool bit.

Well, at least now I can use the lathe!