It was "as expected" because I found a great deal of information about problems with the Shoptask. Why buy one? I also found a lot of people that were really happy with their machines and doing great work after a fair amount of work to get things 5 x 5.

I would also like to point out that Shoptask has been very helpful and prompt in dealing with any issues that I've had. Even though I've had some problems, I'm very happy with the level of customer service.

In terms of capacity and features I felt it was the best out of few choices including units by Smithy and Harbor Freight. The Smithy comes in an extra long lathe model, which would have been nice, but the Shoptask had a much better range of RPM and nifty features like a powered tail-stock. This means you can bore to depth using the DRO. Check this out for a comparison of features.

So what problems did I have?:

1) Items were missing from the shipment. No huge deal, Shoptask was very prompt and helpful in sending out the missing stuff.

2) Looks like I got a metric machine instead of an inch machine...so the 1/2" tools provided with the machine (and all the ones I bought) don't fit in the holders. Also, all the dials are in mm which would be a problem if I didn't get the DRO option. Shoptask offered to replace the tool holders if I sent them back...but I bought a milling machine so I milled them myself.

3) I found on Tangoromeo's site a section about gearbox cleaning. Did I need to do it? Looks like it.

4) I DID NOT have any problems with the alignment on the table as some have. However, my tail stock is just a hair high. I have been using it without adjustment so far, and it seems okay. I haven't turned any long pieces yet.

5) The power cord that came on the machine was wimpy and short. Seemed like about 16 gauge and about 4 feet long. I replaced this cord...not quite as easy as it sounds.

5.5) Tangoromeo also pointed out a problem with the routing on the mill cord. I took his suggestion.

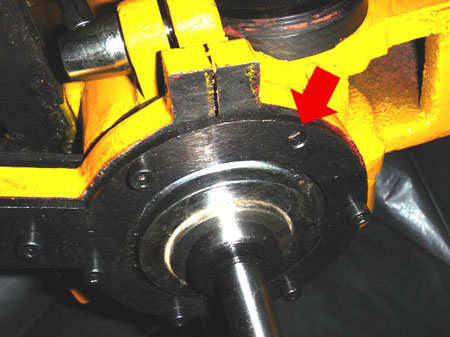

6) When I chucked up my first piece for turning I noticed a wobble that I couldn't get out by re-clamping the piece. I started looking for other problems and notice the gap between the back of the chuck and the faceplate was not even. Upon closer inspection I found that the screws were bottoming out before they were tight. Okay so unbolt the 3 allen screws that hold the chuck on right? Not right. There is not enough space to get the key in there so I had to cut it down. Then I put a stainless washer behind the faceplate to take up the slack. Viola.

7) Oops, looks like the draw bar I got for the mill is also metric. Had to get a new inch size one from Shoptask. Again, helpful and no problems. But...there is no centering washer/shim which means the draw bar turns of center and wobbles the machine and the DRO reading. Neither the metric draw bar or the new standard one had a shim so I figured there wasn't supposed to be one...though the lathe draw bar does. Anyway...I made one!

8) The bolts on the tool holders were really crap. I replaced them with stainless. Ahhhh.

9) My motors have gremlins. Really sneaky ones...they only work part time or something but I can't figure out their schedule. A couple of calls to Shoptask and JT had me in the shop with an open motor can on the lathe. Pretty easy, except for the fan. A few tweaks and I put the motor back together. Works. Now the gremlins have either migrated to the mill or they have multiplied and struck out to claim new territory in the mill. Either way, their motor was getting torn apart.

10) One of the screws from the DRO mounting bracket was missing. The replacement sent by Shoptask was too short.

11) (03/20/06) I was hoping it wouldn't go beyond #10 but here it is:

What are we looking at? The nose of the extended tap handle I bought from Shoptask. The hole is not on center...so neither is my tap...money well spent eh?

12) (03/20/06) Ooooohhh how about another problem? The right hand turning tool has no side clearance. Grind it you whiner? I don't have a grinder and the bit is brazed in such a way that you would have to cut into the tool shaft to grind it. Beauty.

13) (10/08/06) So, I've been having a problem with my table rotating when switching feed directions on the X axis. After plenty of adjusting I can get the rotation down to 1.5 thousandths but no better.

To measure this I attached my magnetic base to the table, chucked up a piece of drill rod and used my indicator on the centerline of the rod.

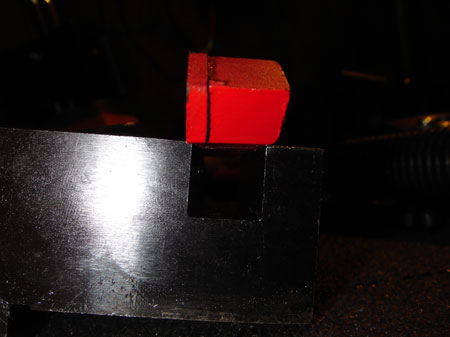

Finally I made another inspection of the gib and found the countersinks for the adjusting/locking screws were drilled out of parallel with the edges of the gib. I'm not sure this is the problem, but I'm going to make a new gib and see if that helps. Let me know if any of you X axis rockers have the same gib problem. Here's a pic.